.jpg)

Construction

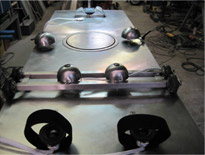

Oorwonde has to evoke a cool and icy feeling, therefore the main part of the work is a stainless steel table, the same type that is used in industrial kitchens as well as for post-mortem examinations. The selection of stainless steel also has a technical benefit: although the layer of steel is very thin (< 1 mm), it still is possible to weld extensions onto the table.

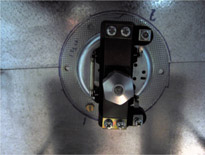

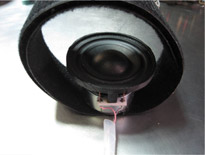

On specific places -namely these places with the highest probability of contact- loudspeakers, electro-magnets and a vibrator motor are built into a stainless steel table.

The contact points for the knees are attached to a sliding system to make the table suitable for diverse human bodies, the contact points for the hands can turn 180 degrees.

Moulded rubber shapes are used to transmit the vibrations.

three electro-magnets

| neck | left hand | left knee |

|---|---|---|

|

|

|

|

|

|

four speakers

| right hand | right knee | both feet |

|---|---|---|

|

|

|

|

|

|

one vibrator motor (buttocks)

one piezoelectric disk (mouth)

lamp

Oorwonde is a very intimate experience where everything is focused on hearing and feeling. To stimulate this a very bright lamp compiled of 5 x 57 white LEDs that shines directly on the face of the visitor is mounted at the head of the table.This insures that the patient closes his or her eyes during the "operation" and can therefore fully concentrate on the triggered movements and sounds.

interaction

Through pushing pressure sensors the visitor activates one or more of the above elements. The sound and the movements change according to the executed pressure.

Underneath the table an 8-channel soundcard, laptop, a controller for the electro-magnets, a controller for the speakers and an ARMmite microcontroller are mounted, out of sight of the visitors.

software

A program in Basic converts the changing voltages from the FSRs to MIDI commands. The Midi commands are read in Pure Data. The commands either evoke pre-recorded sounds or generate real-time sounds of which various parameters change depending on the produced pressure.